How ERPNext Empowers Smarter Production Management

In today’s competitive manufacturing landscape, businesses need more than just skilled labor and machinery — they need smart, connected systems to manage operations efficiently. This blog explores how

How ERPNext Empowers Smarter Production Management

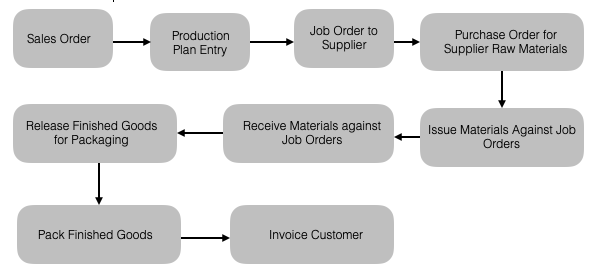

Efficient production goes beyond machines and labor — it’s about having full visibility, control, and integration across all manufacturing operations. The ERPNext Manufacturing Module provides a structured, digital approach to planning, executing, and optimizing production processes — from raw material procurement to product delivery.

Step-by-Step: How ERPNext Streamlines Production

Define Your Product Structure with Bill of Materials (BOM)

A Bill of Materials is the foundation of any manufacturing system. In ERPNext:

- You define what goes into your product: raw materials, sub-assemblies, and operations.

- Each BOM includes quantities, workstations, and estimated costs.

- You can version your BOMs for product updates and custom orders.

➡Example: A table's BOM includes wood panels, screws, glue, and assembly operations.

Plan Production Using the Production Planning Tool

Before manufacturing begins, ERPNext allows you to plan based on demand.

- Analyze Sales Orders, Inventory Levels, and Forecasts.

- The system generates a Material Request Plan to ensure you have enough stock.

- You can convert planned orders into actual Work Orders.

➡Ideal for make-to-order and make-to-stock environments.

Launch a Work Order

A Work Order instructs production teams to manufacture a specific quantity of a product.

- It links to the BOM and specifies required materials and operations.

- ERPNext reserves or transfers raw materials to the Work-in-Progress (WIP) Warehouse.

- The status of the Work Order updates dynamically as tasks are completed.

➡ Real-time status tracking ensures visibility for planners and supervisors.

Track Operations with Job Cards

Each step in the manufacturing process can be tracked using Job Cards:

- Assign operators and workstations to specific tasks (e.g., cutting, sanding, painting).

- Record time taken, materials used, and any issues encountered.

- Capture actual vs planned time for performance analysis.

➡This helps improve labor efficiency and cost accuracy.

Manage Outsourced Processes with Subcontracting

Some manufacturing tasks may be outsourced. ERPNext handles subcontracting by:

- Sending materials to third-party vendors.

- Tracking quantities sent and finished goods received.

- Calculating subcontracting charges accurately.

➡Seamlessly integrates external production into your workflow.

Automatically Update Inventory and Costing

ERPNext tightly integrates production with inventory management:

- Finished products are automatically transferred to the Finished Goods Warehouse.

- Raw material consumption updates stock levels in real time.

- Cost of goods manufactured is calculated based on material and operation costs.

➡Provides accurate inventory valuation and product costing.

Analyze Performance with Real-Time Reports and Dashboards

ERPNext offers built-in reports and analytics, including:

- Work Order Summary

- Production Efficiency Reports

- Material Consumption vs Plan

- Job Card Performance

- Cost Analysis and Wastage

➡ Managers can identify bottlenecks, inefficiencies, and areas for improvement instantly.

ERPNext for Different Manufacturing Industries

ERPNext is highly adaptable and serves a wide range of sectors:

| Industry | Use Case Example |

|---|---|

| Furniture & Woodwork | Track customized product designs and BOMs |

| Food & Beverage | Manage batch production with expiry tracking |

| Textiles & Garments | Handle size variations and subcontracting |

| Electronics | Track serial numbers and assembly workflows |

| Packaging & Printing | Schedule repeat orders and manage variants |

Business Benefits at Every Stage

With ERPNext Manufacturing, businesses experience:

✅ Better coordination between planning, production, and inventory

✅ Timely procurement of raw materials

✅ Reduced waste and downtime

✅ Accurate job costing and profit margins

✅ Real-time visibility across operations

✅ Scalable workflows as your business grows

Before & After ERPNext: A Quick Snapshot

| Category | Before ERPNext | After ERPNext |

|---|---|---|

| Tracking | Manual (Excel, verbal updates) | Automated, real-time dashboards |

| Inventory | Outdated, error-prone | Live updates and smart stock management |

| Production | Uncoordinated, delay-prone | Streamlined, scheduled, and trackable |

| Visibility | Low — dependent on individual input | High — centralized system access |

| Waste | Frequent due to poor planning | Reduced through accurate BOM & forecasting |

Conclusion

ERPNext empowers manufacturers to shift from reactive operations to proactive, data-driven production. Whether you’re running a small workshop or a growing factory, ERPNext gives you the tools to scale efficiently, reduce costs, and deliver with confidence.

Phenom Advisory Limited — Helping businesses unlock the full potential of ERPNext.